TC5100 Multi-Cavity Hot Runner Temperature Controller

Overview

- The TC5100 has multiple advantages, such as an adjustable user perspective from 110° to 145°, a stackable design for the chassis module to save installation space, a front-facing USB port, and a 7-inch color TFT LCD display.

- Moreover, it features built-in 8M + 128M NAND Flash, and offers a choice between a 15A 2-zone or a 30A 1-zone module. The plug-in card design also allows for easy maintenance.

TC5100 Hot Runner Control system

TC5100 Multi-Cavity Hot Runner Temperature Controller produced by ARICO, specially designed for plastic injection molding manufacturers when operating hot runner system. We create the professional hot runner temperature controller for mold temperature monitoring, providing a variety of or customized controllers at a reasonable price. Saving manpower costs, reducing downtime, ensuring segmentation, full heating process, and smooth synchronization, TC5100 Hot Runner Control system have those above advantages effectively strengthen the hot runner on waste recycling and raw material cost management.

| TC5100 | Module |

|

Number of Zones per Module |

15A(2 zones)/30A(1 zone) |

|

Max. Current per Zone |

15A/30A |

|

Input Power |

230Vac±10%/24Vdc±5%, 50/60Hz |

|

Input Thermocouple Type |

J/K type |

|

Output Power |

3450W, 230Vac/15A(per zone); 6900W, 230Vac/30A(per zone) |

|

Output Mode |

Zero cross/Phase angle |

|

Control Accuracy |

±0.25% FS |

|

Measurement Accuracy |

±0.25% FS |

|

Temperature Control Range |

0~600°C/32~999°F |

|

Storage Temperature |

-20~70°C/-4~158°F |

|

Operating Temperature |

-10~50°C/14~122°F |

|

Operating Humidity |

0~80% RH(no condensate) |

|

ID Setup |

Automatic identification(need to work with BUS board) |

|

Indicator Lights |

Output, alarm, fuse open-circuit, communication |

|

Wireless Wi-Fi |

× |

|

Communication Mode |

RS-485(standard MODBUS, isolated) |

|

Communication Speed |

38400/57600 |

|

Temperature Alarm Mode |

Upper limit/Lower limit/Standby upper limit/Standby lower limit/Absolute value alarm |

|

Abnormal Alarm |

Thermocouple: Short/Break/Reverse; Heater: Short/Break/Overload; TRIAC: Short; Fuse open-circuit |

|

Fuse |

Ultra-high speed ceramic type, 250Vac/20A, 30mm |

|

Detection Functions |

Current/Voltage/Fuse open-circuit/Heat sink temperature detections |

| Specs/Model |

TC5100 |

TC5200 |

TC5500 |

TC5600 |

|

Max. Temperature Zones per Link |

36 |

240 |

36 |

240 |

|

Number of Zones per Module |

15A(2 zones)/30A(1 zone) |

|||

|

Max. Current per Zone |

15A/30A |

|||

|

Input Power |

230Vac±10%/24Vdc±5%, 50/60Hz |

|||

|

Input Thermocouple Type |

J/K type |

|||

|

Output Power |

3450W, 230Vac/15A(per zone); 6900W, 230Vac/30A(per zone) |

|||

|

Output Mode |

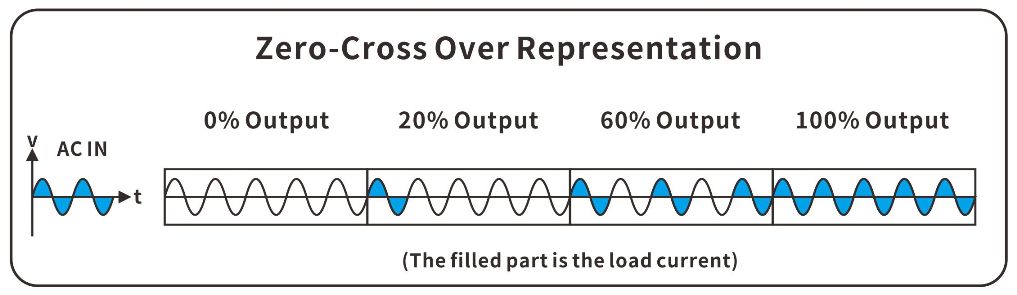

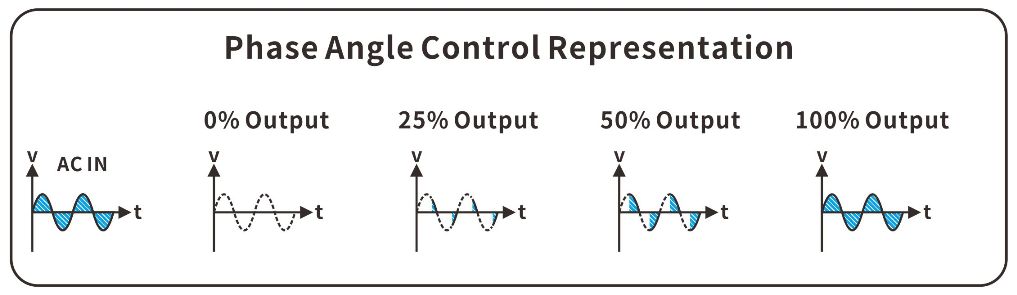

Zero cross/Phase angle |

|||

|

Control Accuracy |

±0.25% FS |

|||

|

Measurement Accuracy |

±0.25% FS |

|||

|

Temperature Control Range |

0~600°C/32~999°F |

|||

|

Storage Temperature |

-20~70°C/-4~158°F |

|||

|

Operating Temperature |

-10~50°C/14~122°F |

|||

|

Operating Humidity |

0~80% RH(no condensate) |

|||

|

ID Setup |

Automatic identification(need to work with BUS board) |

|||

|

Indicator Lights |

Output, alarm, fuse open-circuit, communication |

|||

|

Wireless Wi-Fi |

× |

Wi-Fi 6(802.11ax) |

||

|

Communication Mode |

RS-485(standard MODBUS, isolated) |

|||

|

Communication Speed |

38400/57600 |

|||

|

Temperature Alarm Mode |

Upper limit/Lower limit/Standby upper limit/Standby lower limit/Absolute value alarm |

|||

|

Abnormal Alarm |

Thermocouple: Short/Break/Reverse; Heater: Short/Break/Overload; TRIAC: Short; Fuse open-circuit |

|||

|

Fuse |

Ultra-high speed ceramic type, 250Vac/20A, 30mm |

|||

|

Detection Functions |

Current/Voltage/Fuse open-circuit/Heat sink temperature detections |

Current/Fuse open-circuit detections |

||

Soft Start for Hot Runner Temperature control

Purpose- The heater element used in hot runner is typically made more compact to achieve higher power density. The compact structure of the heater element implies smaller heater coil spacing, and moisture tends to condense more easily within the tight coils of compact heater element. When moisture condenses within the heater element and full power electricity is applied at the beginning of heating, high current/voltage can easily cause the heater element to burn out. To prevent burn out of heater element resulting from over-current caused by high moisture content in it, the Soft Start(de-moisture) function can be enabled so that low-current/voltage heating removes the moisture in the heater element for protection.

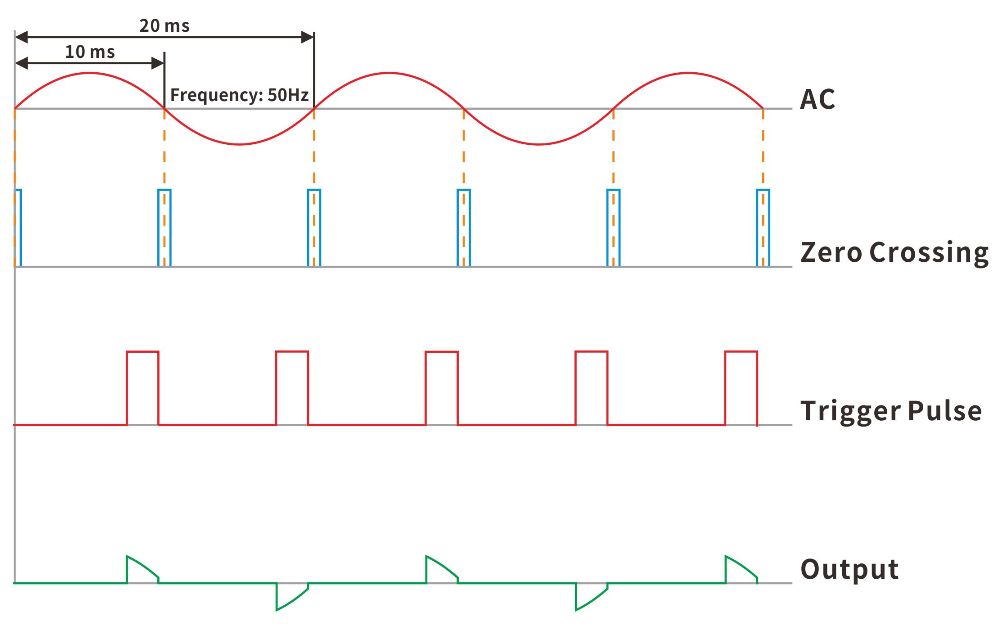

Principle- To provide low current/voltage output on the temperature controller for hot runner, precise control of the AC supplied to the heater is necessary. Refer to the picture below; to precisely control the AC output, it's essential to obtain a synchronous signal with the AC input - the Zero Crossing signal. This allows for accurate timing calculations to trigger the AC output and achieve the desired output ratio.

SOFT START Function-Conditions

1. Soft Start setting is enabled.

2. Heater Temperature below 125℃/257℉.

3. Phase angle 30% output for 1 minute(fixed).

4. After the Soft Start is completed, normal temperature control resumes.